Understanding Injection Robots in Manufacturing

In the realm of industrial manufacturing, automation plays a pivotal role, and injection robots are at the forefront of this transformation. These sophisticated machines are designed to enhance the efficiency and precision of the injection molding process, which is essential in producing high-quality plastic parts across various industries. By integrating Injection Robots into manufacturing lines, companies can capitalize on reduced labor costs, improved safety standards, and superior product accuracy.

What is an Injection Robot?

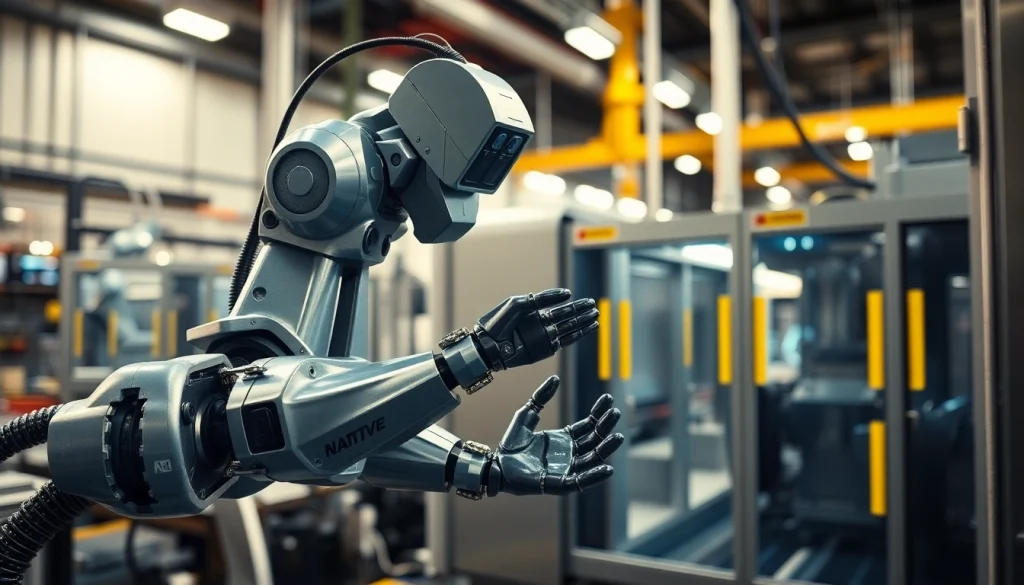

Injection robots are automated machines used in the injection molding process to handle tasks such as part removal, placement, and assembly. These robots are specifically engineered to work alongside injection molding machines, providing seamless integration to enhance production efficiency. The robots can be programmed to execute complex movements with high precision, making them invaluable in today’s fast-paced manufacturing environments.

Key Components of Injection Robots

Understanding the components of injection robots is crucial for manufacturers looking to optimize their operations. Key components include:

- End Effectors: The tools or devices attached to the robot’s arm, designed to grasp and manipulate molded parts.

- Controller: The brain of the robot, which processes inputs and directs the robot’s actions based on programmed instructions.

- Actuators: These convert energy into motion, allowing the robot to perform precise movements.

- Vision Systems: Some advanced robots come equipped with cameras and sensors that aid in detecting the position and orientation of parts.

The Role of Injection Robots in Modern Manufacturing

Injection robots play a critical role in modern manufacturing by streamlining processes, ensuring consistency, and reducing operational costs. They not only enhance the speed of production but also minimize the chances of human error, leading to improved product quality. Moreover, robots can work in environments that are hazardous for humans, thereby increasing workplace safety.

Benefits of Using Injection Robots

Enhancing Precision and Efficiency

One of the most significant advantages of using injection robots is their ability to enhance precision. Unlike human operators, robots can perform repetitive tasks with pinpoint accuracy, ensuring that every part produced meets stringent quality standards. This precision translates into less waste and higher overall production efficiency.

Reducing Labor Costs with Automation

By automating the injection molding process with robots, manufacturers can significantly reduce labor costs. Robots can operate continuously without breaks, which maximizes output and minimizes the need for large workforces. Over time, the savings generated from reduced labor and increased productivity can be substantial, allowing companies to reinvest in other areas of their operations.

Improving Production Safety Standards

Safety is paramount in any manufacturing environment. Injection robots can take over dangerous tasks, such as handling hot molds or heavy parts, thus protecting human workers from potential injuries. Additionally, by minimizing human involvement in hazardous areas, companies can create a safer work environment, contributing to better overall health and safety compliance.

Challenges in Implementing Injection Robots

Common Misconceptions About Injection Robots

Despite their benefits, there are several misconceptions surrounding injection robots. One major myth is that they are too expensive for small to mid-sized manufacturers. In reality, the return on investment can be realized quickly through increased efficiency and reduced labor costs. Understanding the true cost and benefits of injection robots can help businesses make informed decisions.

Technical Challenges and Solutions

Implementing injection robots can pose technical challenges, including integration with existing systems and ensuring compatibility with various types of molds. Manufacturers must conduct thorough assessments of their production lines and work closely with robot suppliers to address these challenges. Solutions may include custom programming and modifying existing equipment to accommodate robotic integration.

Integrating Robots into Existing Production Lines

Successful integration of injection robots into existing production lines requires careful planning. Companies must assess workflows, identify potential bottlenecks, and determine the best strategic placement for robots to maximize their impact. Engaging in thorough training for staff is also essential to ensure a smooth transition to automated processes.

Best Practices for Utilizing Injection Robots

Choosing the Right Injection Robot for Your Needs

Selecting an injection robot that meets specific production needs is a critical step. Factors to consider include the size and weight of parts, required precision, and the complexity of tasks to be performed. Custom solutions may be necessary for unique applications, while standard robots may suffice for more straightforward tasks.

Maintaining and Upgrading Injection Robots

Like all machinery, injection robots require regular maintenance to ensure optimal performance. Establishing a routine maintenance schedule can help prevent costly downtime. Additionally, manufacturers should stay informed about technological advancements and consider upgrades to keep their systems efficient and competitive.

Training Staff for Optimal Robot Utilization

Training is essential for maximizing the benefits of injection robots. Staff should be educated not only on how to operate the robots but also on troubleshooting and basic maintenance procedures. Investing in staff training can lead to higher productivity and a more skilled workforce, ultimately benefiting the organization as a whole.

Future Trends in Injection Robot Technology

Emerging Technologies in Injection Robotics

The future of injection robotics is bright, with advancements in artificial intelligence (AI) and machine learning driving innovation. These technologies enable robots to adapt to changing production conditions in real-time, improving efficiency further. Moreover, AI-powered robots can analyze data from operations to enhance performance and predict maintenance needs.

The Impact of AI on Injection Robot Performance

Artificial intelligence is set to revolutionize injection robots by enabling them to learn from their experiences. This capability allows robots to optimize their operations continually, making them more efficient over time. As AI technology evolves, it is likely that robots will become more autonomous, requiring less human intervention and further reducing labor costs.

Predictions for the Future of Manufacturing with Injection Robots

As we look towards 2025 and beyond, the role of injection robots in manufacturing is expected to grow exponentially. With the increasing demand for production flexibility and customization, manufacturers will rely more on robots that can handle low-volume, high-mix production efficiently. The integration of advanced technologies such as IoT will facilitate better connectivity and data sharing, further enhancing the capabilities of injection robots.